Value Stream Identification

This article introduces the concept of Value Stream Identification (VSI) and explains how it helps organizations gain clarity about how value is delivered. It outlines practical tools like the Value Stream Canvas and the Assembly Line Model, and emphasizes why simply visualizing a value stream is not enough.

„When you improve a system, start by making the work visible.“ – Gene Kim

Describing a Value Stream

A value stream is the end-to-end sequence of activities required to deliver value to a customer – spanning concept, creation, and delivery. These streams exist in every organization, but they’re rarely visible or well understood. As already discussed in the article Why Value Stream Thinking, it is essential to define what a value stream actually is and ensure a shared understanding among stakeholders before attempting to identify them.

The conceptual representations commonly found in books and presentations provide a helpful first impression of what a value stream is – but they are not sufficient for actually identifying and improving value streams within your organization.

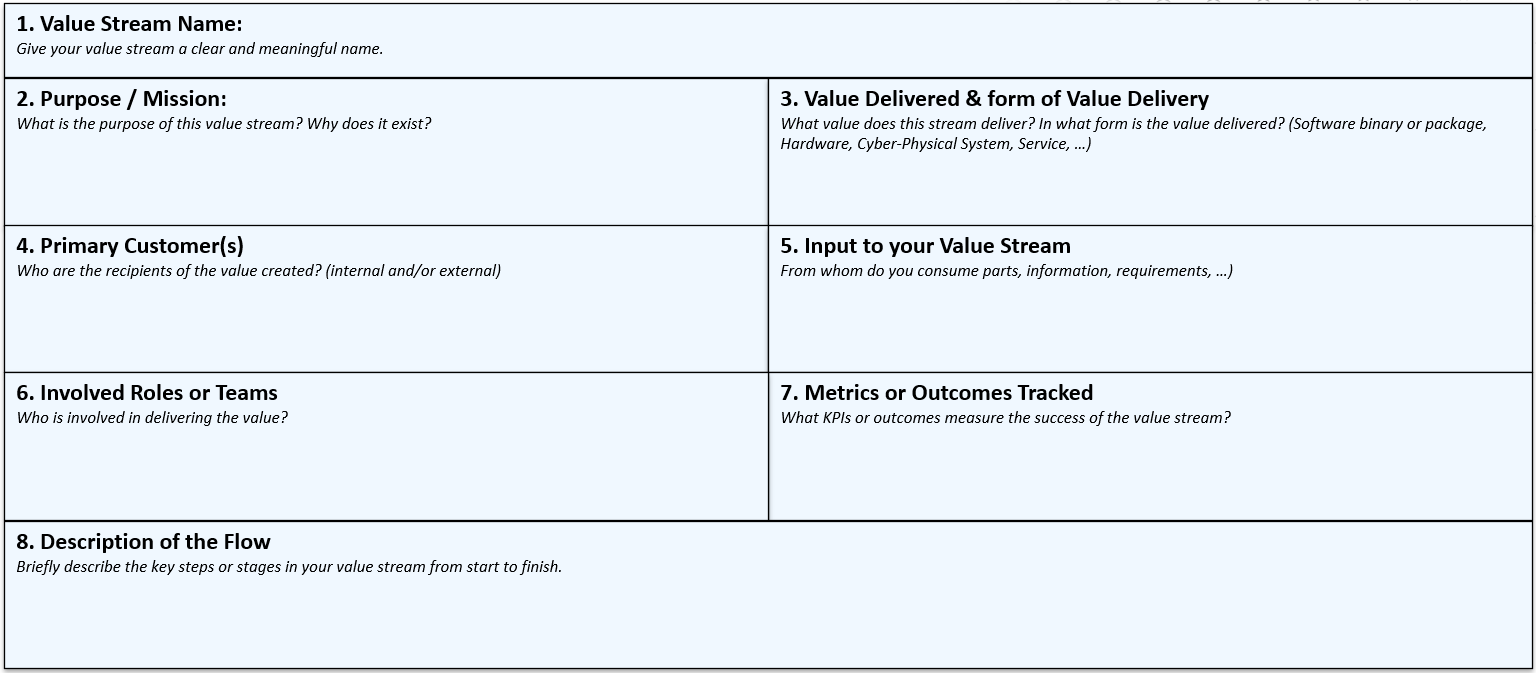

While this offers some initial insight, the key question remains: How do you actually describe a value stream? What information is relevant and necessary to capture it in a meaningful way? A focused and practical answer is provided by the Value Stream Canvas. Like any canvas, its purpose is to present a clear, concise, and structured view – here, of the value stream. It distills the essential elements into a format that fosters alignment, improves communication, and enables actionable insights.

Another important consideration is the intended purpose of the canvas. In our case, we are focusing specifically on Development Value Streams. Experience has shown that the following canvas structure is well-suited to this context and provides a solid foundation for capturing the relevant aspects effectively.

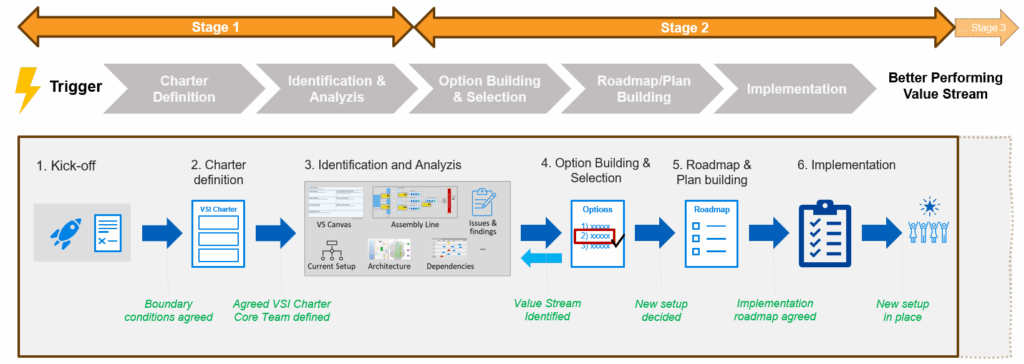

The end-to-end process for conducting a Value Stream Identification (VSI) is outlined in the article “How to Start – Single Value Stream”. For better orientation, the process diagram is shown below.

The Value Stream Canvas plays a central role in the Identification and Analyzis phase and is complemented by other supporting artifacts. In particular, the Assembly Line Model serves as a valuable input to the canvas – it helps sharpen the value stream description and enrich it with information about flow, structure and involved people & teams. Guidance on how to use the Assembly Line for Value Stream Identification can be found in the Article: Using the Assembly Line Approach for Value Stream Identification. A third valuable deliverable is the Issues & Findings List. It is inevitable that during Value Stream Identification activities, current issues within the value stream will be uncovered and discussed. To capture these observations without derailing the identification process, they are documented in a structured Issues and Findings list. This approach ensures that valuable insights are not lost, and that the team remains focused, avoiding lengthy side discussions or premature problem-solving. The list is later refined and serves as a key input for developing future-state proposals that directly address the identified issues.

Value Stream Identification should be complemented with „Organizing around Value“

After creating the Value Stream Canvas, the Assembly Line Model, and the Issue List, we gain a strong understanding of the current state of the value stream – and could, at first glance, consider the VSI complete. However, these insights alone don’t lead to improvement. To create real impact, the next logical step is to envision a future state: a redesigned value stream that addresses key issues and enables more effective value delivery.

That’s why we typically view Value Stream Identification (VSI) not just as an analysis activity, but as the first step toward reorganizing around value. In larger organizations, it may be appropriate to pause at this point – using the results to prioritize which value streams to address first. Given limited resources, improvements must often be sequenced strategically, based on business impact, urgency, and readiness for change.

There are various ways to improve a value stream – ranging from continuous improvement through targeted Kaizen bursts, to defining a future state, or even envisioning an ideal state1. Choosing the right approach is critical, as it determines the degree of achievable performance and improvement. We recommend the following stages:

Stage 1: Value Stream Identification

Begin by developing a high-level understanding of the value stream to gain clarity on its current state. This involves identifying key attributes using tools such as the Valu

Stage 2: Initial setup of the Value Stream: Organize around Value

Simply identifying a value stream does not create impact on its own. To realize benefits, the identification is typically followed by a new, improved setup – guided by the principle of organizing around value. This may include structural or team changes that better align with the value stream’s flow.

Stage 3: Continuous, systematic improvement of the Value Stream: Value Stream Optimization

Once the structure is in place, the focus shifts to continuous optimization – both of the value stream itself and of the methods used to measure its performance. Improving only the existing structure risks achieving only a local optimum. A broader perspective enables movement toward a global optimum.

Only the first two stages fall within the scope of Value Stream Identification (VSI); the third stage is part of Value Stream Optimization (VSO), which focuses on systematically and continuously improving value stream performance and enhancing the ability to measure it effectively.

Global versus Local Optimum – The Importance of Stage 2

„Some changes, by their very nature, cannot be incremental.

They need the introduction of a fundamental change – a break with the past.„2

– James Martin

We include organizing around value as part of the Value Stream Identification (VSI) activity for a simple reason: it unlocks significant improvement potential.

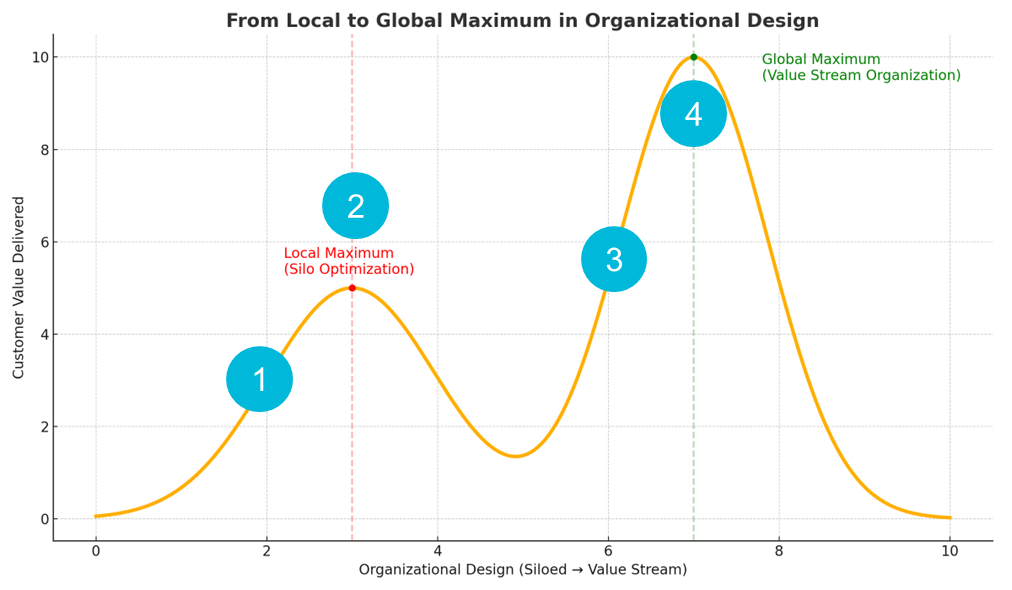

To illustrate this, consider the difference between two improvement strategies:

Continuous improvement focuses on making incremental gains within the boundaries of the existing system. These efforts, while valuable, are constrained by the current organizational structure and its inherent limitations.

Organizing around value, on the other hand, is a transformative step. It involves realigning teams, responsibilities, and workflows to reflect the actual flow of value. This structural change lays a far stronger foundation for meaningful, sustainable improvement.

By embedding this reorganization step into the identification phase, we do more than describe the value stream – we begin to actively shape it for better performance outcomes.

Let’s visualize this idea:

The local maximum (point 2, in red) represents the best performance achievable through continuous improvement within the current setup (point 1).

However, if we first organize around value, we move to a fundamentally better starting point (point 3). From there, we can pursue targeted optimization to reach a global maximum (point 4, in green), where value stream performance is significantly higher and more sustainable.

In short:

(3 → 4): Full potential unlocked through targeted optimization

(1 → 2): Limited gains within existing constraints

(1 → 3): Structural shift through organizing around value

Conclusions

Value Stream Identification (VSI) provides a structured way to visualize and describe how value flows through an organization. Using tools like the Value Stream Canvas, the Assembly Line Model, and an Issue List, teams gain a clear, shared understanding of the current state – its boundaries, key roles, delivery mechanisms, and challenges. This visibility creates alignment and lays the groundwork for informed decision-making.

However, visibility alone does not lead to improvement. To unlock meaningful and sustainable gains, organizations must take the next step: organizing around value. This structural shift removes existing constraints and creates the conditions necessary for reaching maximum performance.

References

- See e.g. Chapter 8 in Pereira, Steve; Davis, Andrew. Flow Engineering: From Value Stream Mapping to Effective Action (English Edition) (S.129). IT Revolution Press. Kindle-Version. ↩︎

- Martin, J. (1995). The Great Transition: Using the Seven Disciplines of Enterprise Engineering to Align People, Technology, and Strategy. AMACOM.

James Martin came to a similar conclusion nearly 30 years ago. In Chapter 18, “TQM vs. Revolution,” he explores the pros and cons of continuous improvement versus fundamental redesign – emphasizing that, in some cases, breakthrough change must come first, before incremental improvements can be effective. We advocate a similar approach today: first organize around value, then begin optimizing the redesigned system. ↩︎

Author: Peter Vollmer – Last Updated on September 10, 2025 by Peter Vollmer